Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf

Heat exchangers are almost the most widely used member in chemical processes and can be seen in most industrial units. They are devices that allow the transfer of thermal energy between two or more fluids at different temperatures. This operation can be performed between liquid-liquid, gas-gas or gas-liquid. Heat exchangers are used to cool a hot fluid or to heat a fluid to a lower temperature, or both. for more information study download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf . for more free solution manual click here.

download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf are used in a wide range of applications. These applications include power plants, refineries, petrochemical industries, manufacturing industries, process industries, food and pharmaceutical industries, metal smelting industries, heating, air conditioning, refrigeration systems and space applications. Heat exchangers in various devices such as boilers, steam generators, condensers, evaporators, evaporators, cooling towers, preheating fan coils, oil coolers and heaters, radiators, furnaces, etc. have.

Download Link

download heat exchangers kakac 3rd edition solutions manual

Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf

Many industries are involved in the design of various types of heat exchangers, as well as several courses in colleges and universities with different names in the design of heat exchangers. IN download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf Converter calculations are a long and sometimes tedious task. For example, designing a converter for a particular operation requires a lot of guesswork that can be used to find the right size of a converter according to the standards. But with the use of computer programs, all these calculations are done by the computer, and the designer only has to enter the operating conditions and the properties of the fluids present in the operation to design.

download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf can be classified into three groups of low pressure, medium pressure and high pressure in terms of fluid working pressure. But often the study of heat exchangers is based on their design structure, which are:

Types of heat exchangers

1- Double Pipe heat exchanger (Double Pipe):

The simplest converters used in the industry are double tube heat exchangers, also known as tubular heat exchangers and described in download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf . On the one hand, the cheapness of these converters, both in terms of design and maintenance, has made them a good choice for small industries, and on the other hand, their low efficiency as well as large space occupation on a scale Large, has led to less use in today’s modern industries and more efficient converters such as shell and tube converters and plate converters. The structure of a tubular heat exchanger, in its simplest form, consists of two tubes of different diameters, the smaller tube being centrifuged inside the other tube.

2- Shell and Tube heat exchanger:

One of the most common types of converters in various industries, including air conditioning and industrial refrigeration, is the shell and tube heat exchanger described in download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf . As the name implies, these converters consist of a number of tubes that are housed inside a cylindrical shell. Two fluid streams with different initial temperatures enter the exchanger. One passes through the tubes and the other through the shell (outside the tubes). Heat is transferred through the wall of the pipes, between two fluids, sometimes from the fluid inside the tube to the fluid flowing in the shell and sometimes vice versa.

Each of the fluids can be liquids or gases, and it is possible for each to flow through a tube or shell. A transducer in which only a liquid or only a gas is flowing on either side (inside the shell and the tube) is called a single-phase transducer. Two-phase converters can be used to transfer heat to a liquid for boiling and evaporating it (boiler) or to cool steam to condense it (condenser) by phase change, which occurs mainly on the shell side.

Application of tubular and tube heat exchangers

Tubular converters are suitable for applications where either the flow rate of the passing fluids is low and large temperature variations are required, or low heat transfer is required for high flow rates. Of course, given the dimensions of tubular converters, it would make sense to use them when there is enough space. It is worth mentioning that in order to create more capacities, several pipe converter units can be installed in series or in parallel with each other, vertically. download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf .Tube heat exchangers are most widely used in the food industry as well as air conditioners (such as boilers, evaporators or condensers).

Shell and tube heat exchangers can be considered as the most common type of heat exchangers that are mainly used for cooling or heating liquids and gases and described in download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf . Their design flexibility has made it possible to use the converter at different temperatures and pressures and with different fluids. Shell and tube heat exchangers are widely used in processes that require cooling or heating a large volume of liquid or gas flow. Some common applications of shell and tube heat exchangers are: power plant, HVAC, refrigeration, paper production, pharmaceuticals, petrochemicals and refineries, sulfuric acid production, mines and

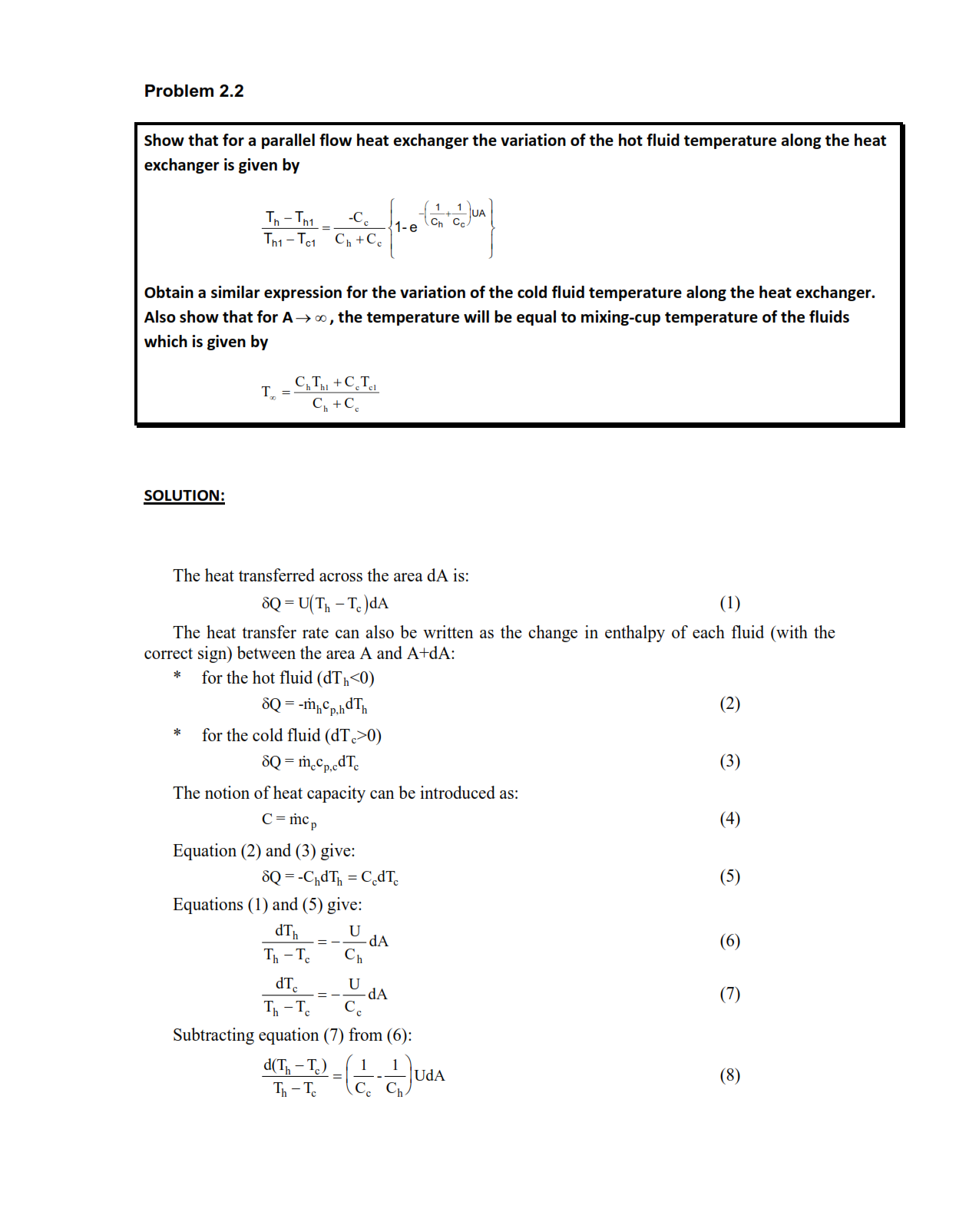

Sample images from the file:

download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf

download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf

download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf

download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf

download free Solution manual ( solutions ) Heat Exchangers by kakac | Selection , Rating and Thermal Design 3rd ( third ) edition eBook pdf

Download Link

heat exchangers kakac 3rd edition solutions manuals pdf ebook